Was beschädigt die elektrische Zahnstange eines Autos?

Die Vermeidung unsachgemäßer Lenkvorgänge ist eine wichtige Maßnahme zur Reduzierung von Schäden an der elektrischen Zahnstange. Vermeiden Sie beispielsweise häufiges Drehen des Lenkrads im Stand, insbesondere Übersteuern bei langsamer Fahrt oder beim Parken. Eine gezielte Lenkkontrolle trägt nicht nur zur Verlängerung der Lebensdauer der Lenkung bei, sondern verhindert auch effektiv eine übermäßige mechanische Belastung der Zahnstange.

3. Sorgen Sie für einen einwandfreien Betrieb der elektrischen Anlage

Überprüfen Sie regelmäßig die elektronische Steuereinheit, den Motor und die Batterie des elektrischen Lenksystems, um den normalen Betrieb des elektrischen Systems sicherzustellen. Wenn ein elektrischer Fehler festgestellt wird, sollten die entsprechenden Teile rechtzeitig repariert oder ausgetauscht werden, um zu verhindern, dass die elektrische Zahnstange aufgrund elektrischer Probleme beschädigt wird.4. Vermeiden Sie gewalttätiges FahrenVermeiden Sie eine heftige Fahrweise, insbesondere auf unebenen Straßen oder in scharfen Kurven, um die Belastung des Lenksystems zu verringern und eine Beschädigung der Zahnstange durch Überlastung zu verhindern.

5. Achten Sie auf Umweltfaktoren

Verstehen Sie die Auswirkungen der Umgebungsbedingungen auf das Fahrzeug und passen Sie sich daran an. Achten Sie insbesondere bei kaltem und heißem Wetter besonders auf den Betriebszustand des elektrischen Lenksystems, um Schäden durch Umweltfaktoren zu vermeiden.

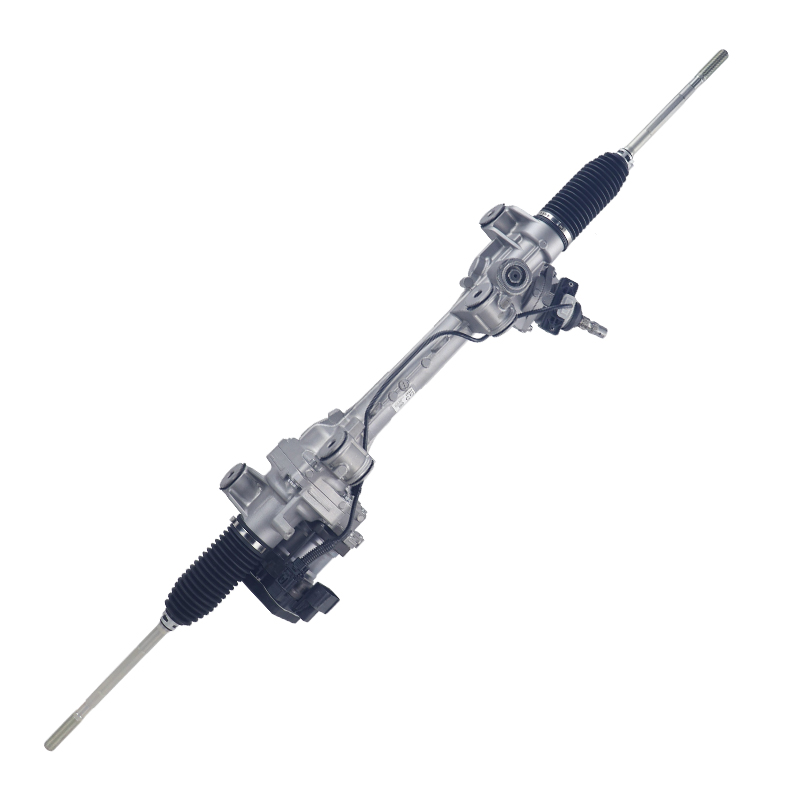

Premium-Servolenkgetriebe zu ermäßigten Preisen

Suchen Sie hochwertige Servolenkungen zu reduzierten Preisen? Guangdong Diamond Auto Parts Co., Ltd. (DKM) bietet Premium-Lenksysteme für führende Fahrzeugmarken wie Toyota, Honda und Mitsubishi. Unser Werk in Foshan, China, nutzt modernste Maschinen zur Herstellung zuverlässiger und erschwinglicher Produkte.

Wir sind auf Standard- und kundenspezifische Lenkgetriebelösungen spezialisiert und bieten Großabnehmern flexible Kaufoptionen. Kontaktieren Sie uns für weitere Informationen und ein individuelles Angebot.

Through the above principles, the electric steering system can provide the driver with a precise and smooth steering experience with lower energy consumption and higher efficiency. The electric steering rack plays a key role in the system to convert the rotational force of the electric motor into wheel rotation. Therefore, damage to the rack may directly affect the accuracy and comfort of steering.

What are the situations that lead to damage to the electric steering rack?

Although the electric steering system has higher stability and less mechanical wear than the traditional hydraulic steering system, the electric steering rack may still be damaged in some specific situations. The following are some common situations that may cause damage to the electric steering rack.

1. Excessive use or long-term overload operation

The design of the electric steering rack is based on a certain intensity of use and load conditions. If the vehicle is overloaded for a long time, or during long-term high-speed driving, frequent parking and steering, the electric steering system may encounter excessive load. In this case, the working state of the electric motor and the rack will be under high pressure, resulting in excessive wear on the contact surface between the rack and the gear, which in turn affects the stability and accuracy of the system.

For example, frequent steering and excessive turning of the steering wheel, especially turning the steering wheel at low speed or parking, will cause the electric steering rack to be subjected to excessive pressure. Over time, the tooth surface in the rack may be worn, deformed or loose, resulting in inflexible steering operation and even rack damage.

2. Electrical failure of the electric steering system

One of the core components of the electric steering system is the electric motor, whose operation depends on the supply of current and the normal operation of the electrical control system. If the electrical system of the electric steering system fails, such as problems with the electronic control unit (ECU), unstable power supply or failure of the electric motor control system, it may cause the electric motor to output excessive power or unstable power supply.

When the electric steering system cannot provide stable power assistance, the steering rack may be subjected to abnormal loads, causing excessive wear or deformation of its tooth surface. At this time, even if the driver does not apply too much force, the contact between the rack and the gear may still have irregular impacts, causing damage. Electrical failures may also cause power assistance to be abnormal, causing the mechanical structure of the electric steering rack to be under greater pressure.

3. Mechanical failure of the steering system

The normal operation of the electric steering rack is inseparable from the synergy of other components in the steering system. For example, if the connecting parts between the steering column, steering tie rod and rack are loose, damaged or improperly installed, it may also affect the normal operation of the rack. Failure of mechanical components may cause the electric steering rack to be disturbed by external forces during operation, causing damage.

For example, the looseness of the steering tie rod can cause the rack to generate abnormal torque during operation, resulting in excessive or too small clearance between the rack and the gear, or even poor meshing, which will lead to unstable system operation, abnormal noise, and accelerated wear of the rack.

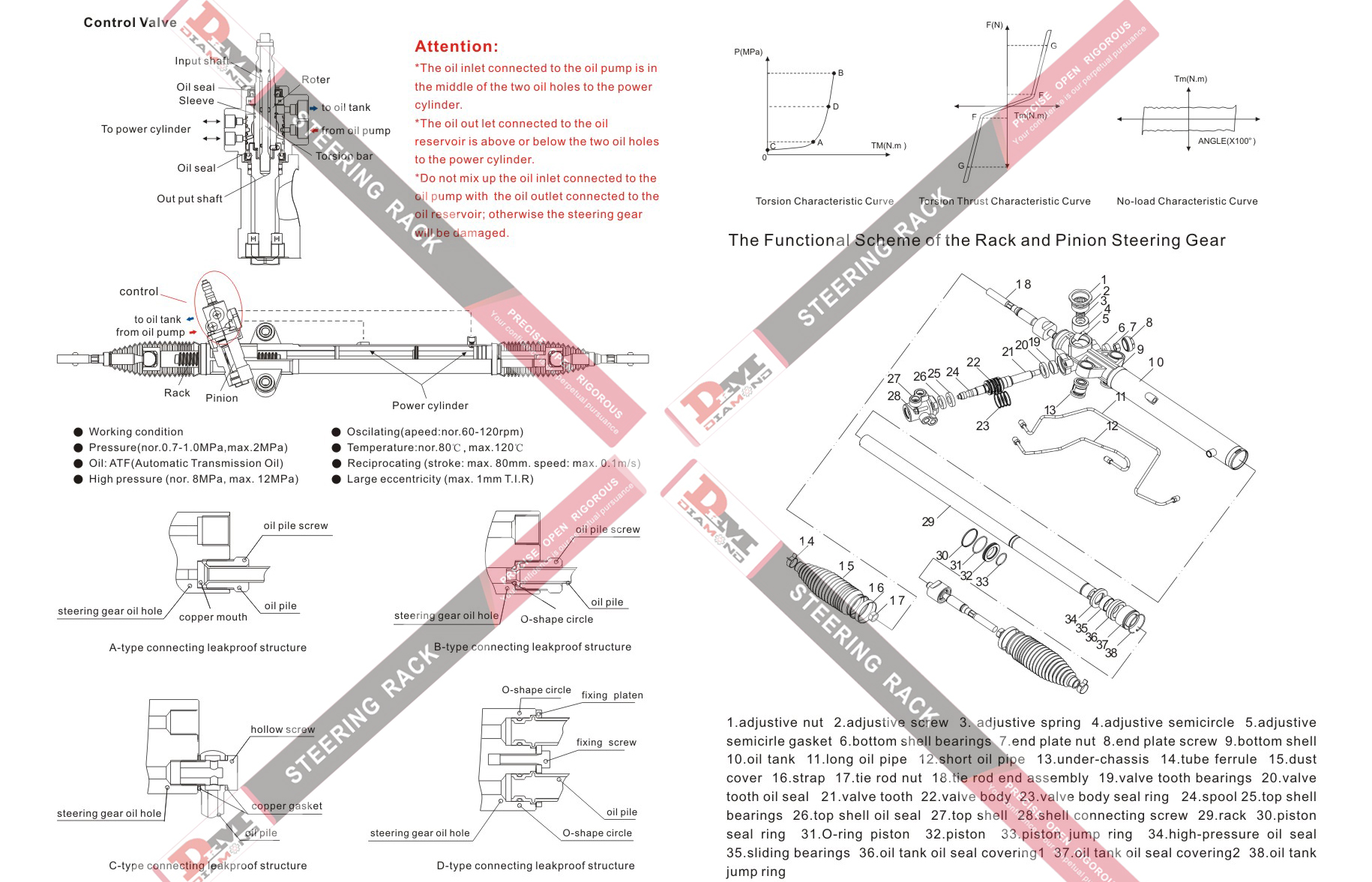

4. Hydraulic oil contamination or leakage (for hybrid steering systems)

For some hybrid or dual-mode steering systems, the role of hydraulic oil in the system is to support the operation of the electric motor and ensure the smooth operation of the steering system. If the hydraulic oil is contaminated or leaks, some mechanical parts of the electric steering system may not be properly lubricated or bear excessive friction, eventually causing damage to the electric steering rack.

There are many reasons for hydraulic oil contamination or leakage, including aging of oil seals, broken pipes, oil pump failure, etc. In this case, the working pressure of the electric steering system may fluctuate violently, affecting the normal operation of the rack, and even causing severe wear or breakage.

5. Vehicle accidents or violent collisions

When a vehicle has an accident or encounters a violent collision, the steering system, especially the electric steering rack, often bears a large impact force. Severe external impacts may cause the steering rack to deform, damage, or interfere with other components, affecting the normal function of the system. Even if there is no obvious external damage, the internal tooth surface may crack or deform due to the impact, causing the rack to gradually fail.

Especially in accidents with more serious impacts, the chassis and steering system of the vehicle will be under great pressure, and the electric steering rack may also be damaged due to mechanical effects exceeding the design load.

6. Impact of environmental factors

The impact of external environmental factors on the electric steering system cannot be ignored. In particular, extreme weather with high or low temperatures may cause the performance of the electric motor, electronic control unit and circuit part of the electric steering system to deteriorate. In cold weather, the starting current of the electric motor may increase, resulting in excessive system load, thereby aggravating the wear of the rack. In high temperature environments, the lubricating oil or battery in the steering system may overheat, affecting the normal lubrication and operation of the rack.

In addition, corrosive substances such as moisture and salt may also corrode the electric steering rack and other components, causing system performance degradation or damage.

How to prevent damage to the electric steering rack?

1. Regular maintenance and inspection

To prevent damage to the electric steering rack and other steering system components, car owners should perform regular maintenance and inspections, especially checking key components of the steering system during the car's maintenance cycle. This includes checking the lubrication of the electric steering system, hydraulic oil (if applicable), electric motor, steering rack, and whether the connections of all components in the steering system are secure.

2. Avoid improper operation

Avoiding improper steering operation is an important measure to reduce damage to the electric steering rack. For example, try to avoid turning the steering wheel frequently when stationary, especially oversteering when driving at low speed or parking. Reasonable control of the use of the steering wheel will not only help extend the service life of the steering system, but also effectively prevent the rack from being subjected to excessive mechanical burden.

3. Keep the electrical system working properly

Regularly check the electronic control unit, motor and battery of the electric steering system to ensure the normal operation of the electrical system. If an electrical fault is found, the relevant parts should be repaired or replaced in time to prevent the electric steering rack from being damaged due to electrical problems.

4. Avoid violent driving

Avoid violent driving, especially on rough roads or in sharp turns, to reduce the load on the steering system and prevent damage to the rack due to overload.

5. Pay attention to environmental factors

Understand and adapt to the impact of environmental conditions on the vehicle, especially in cold and hot weather, pay special attention to the working state of the electric steering system to prevent damage caused by environmental factors.

Premium Power Steering Gears at Discounted Prices

Looking to purchase high-quality power steering gears at discounted prices? Guangdong Diamond Auto Parts Co., Ltd. (DKM) offers premium steering systems for leading vehicle brands like Toyota, Honda, and Mitsubishi. Our factory, based in Foshan, China, uses state-of-the-art machinery to produce reliable and affordable products.

We specialize in both standard and custom steering gear solutions, providing flexible purchasing options for bulk buyers. Contact us for more information and a customized quote.

2. Vermeiden Sie Fehlbedienungen